Brushless DC motor (BLDC) is an efficient and reliable motor, consisting of two main parts: the motor body and the driver. The product adopts electronic commutation technology, replacing the carbon brushes and commutators in traditional DC motors, effectively avoiding energy loss caused by friction, thereby significantly improving the service life of the motor. BLDC motors also have excellent power density and torque density, enabling precise speed and position control. It’s widely used in the automotive industry, aviation drones, consumer electronics, and other fields.

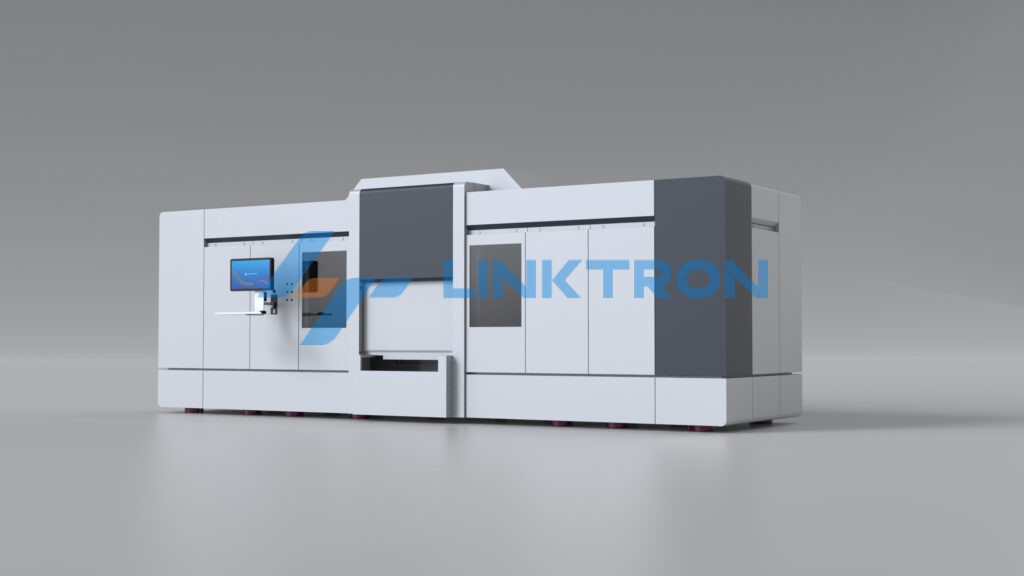

We provide assembly and testing solutions for brushless motors based on specific customer needs. These production lines are flexible and can adapt to be compatible with the production needs of customers for various potential products by changing different fixtures.